Infrastructure

Type of Process - Key Process

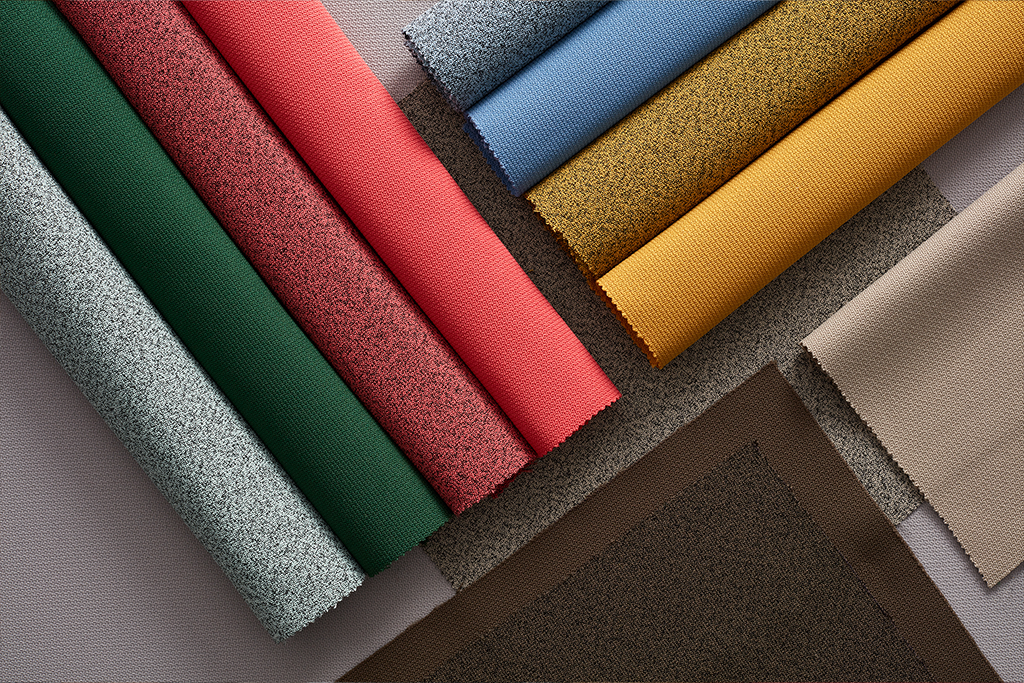

Aruna boasts an impressive capacity to dye 12 tonnes of yarn and process more than 200,000 meters of fabric per day with its advanced dye vats and automated systems. From vibrant hues to subtle hues, Aruna caters to a wide range of customer requirements and preferences.

But it’s just not about the quantity. Quality is paramount and we adhere to strict quality control measures in every stage of the dyeing process. Our commitment to improving the dyeing process with eco-friendly formulations, rigorous testing and quality control measures sets us apart from the rest.

Aruna turns blank canvases into brilliant art works through its latest printing

machinery which are capable of handling 75,000 meters of fabric per day. Our 12 color rotatory printers can handle up to 60,000 meters per day and our table top printing can do an impressive 5000 meters.

At Aruna, we believe we have a great responsibility in protecting our environment and our idea reflects in many areas of our production. We prefer eco-friendly printing inks which are less polluting than conventional inks.

Aruna’s sewing floor is the heart of the factory where creativity meets craftsmanship and precision. With 500 sewing machines in the floor, we’re equipped to handle projects of any volume with efficiency and expertise.

Equipped with the latest sewing machines, we’re ready to deliver any complex design or pattern based on customers’ requirements. By using the latest machinery, we stay ahead of trends pushing the boundaries of textile manufacturing.

Key Highlights of our Production Facility

Dyeing capacity – 150000 meters of fabric per day

Weaving – Plain & Textures, Stripes, Plaids, Cotton-linen blends, Terry, Waffle to weave up to 280cms wide fabric.

Screen/ Table top printing up to 5000 meters per day

HTHP yarn dyeing capacity of 11 tons per day

Cut & Sew with over 500 machines with multiple operations

12 Color rotatory printing up to 60,000 meters per day

Color Mastery, Eco Excellence: Aruna Textiles

Embark on a journey of color mastery as Aruna Home Fashions unveils its astounding dyeing capacity of 150K meters of fabrics per day. From the timeless allure of 100% cotton to the sleek sophistication of polyester, our palette extends to embrace the richness of viscose, poly cotton, poly viscose, cotton viscose, linen, flax, and jute. At Aruna Home Fashions, we take pride in our commitment to the environment.

Our Services

Delivering the Highest Quality of Thread in Every Fabrics

Let’s explore the commitment of Aruna Home Fashions towards quality, efficiency, and sustainability to provide a better understanding of how our products are made.

Weaving

We specialize in creating personalized pieces that cater to your unique preferences and needs, ensuring that your home looks and feels just how you want it to. Let us help you transform your space with our expert sewing skills and attention to detail.

Wet Processing

Wet processing service in home textile fashions involves a range of techniques such as washing, dyeing, printing, and finishing to enhance the look, feel, and functionality of fabrics. This service helps to achieve aesthetic effects, improve durability & performance,

Sewing

Our weaving service in home textile offers custom-made fabrics that are woven with precision, creativity, & high-quality materials to match your style Whether you want to refresh your living room decor or bedroom, our weavers can turn your vision into reality.

Browse Our Latest Collections & Find Your Perfect Style for Your Home Fashions

We’re a leading home textile manufacturer and distributors in Erode. Complete fashion solutions for your sweet home.

Home Textile Fashion Capabilities to the Core

Transform Your Home with Our Stylish Textiles & Discover the Perfect Textures for Your Dream Home. Aruna Home Fashions – Balancing the Quality & Style!

Key Processes

Innovation Woven in Style with Precision Quality